Forging can be carried out by many methods, some of which are listed below:

Wrought Product Defects

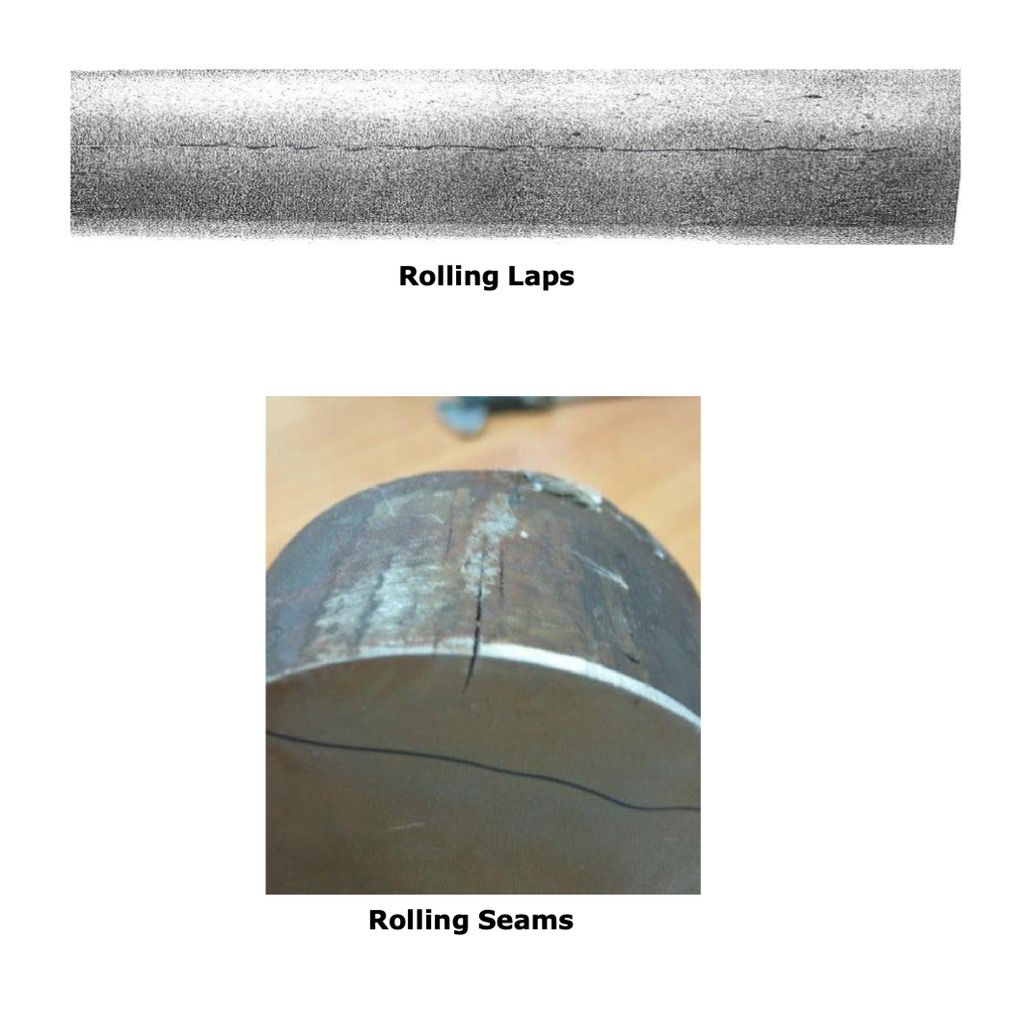

Laps

Forging laps are caused by metal being folded over and flattened but not fused onto the surface of the forging. Laps can be produced by using faulty/ oversized dies/ misaligned dies particular reference to the closed die forging process or too greater reduction attempted when rolling plate/strip causing a back up of material which eventually is pulled through the rolls folding back onto the plate/strip surface.

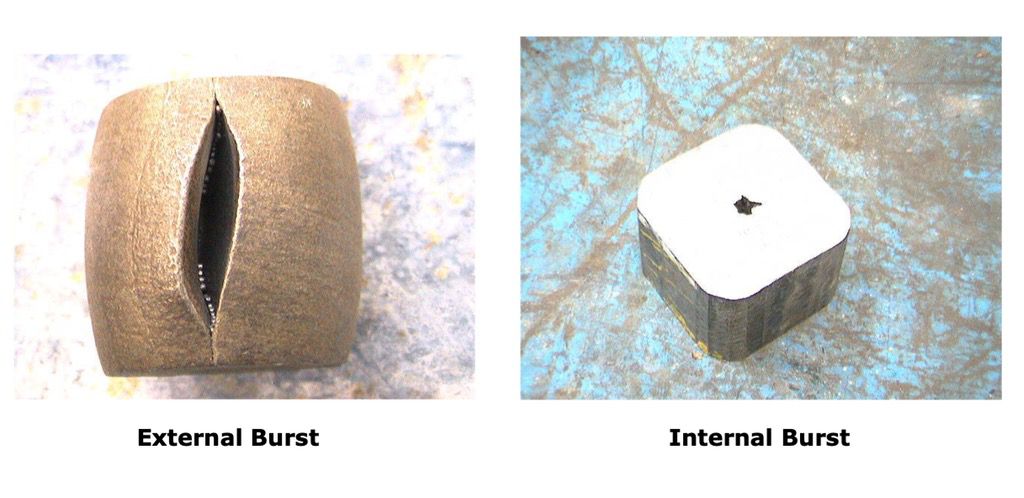

Bursts

Forging bursts are surface or internal ruptures caused by processing at too low a temperature, excessive working or metal movement during forging.

Internal Bursts are generally formed due to insufficient heating of the steel in the furnace prior to forging. External Bursts are generally formed due to allowing the steel to cool after removal from the furnace prior to forging. Therefore timing is critical from furnace removal to forging the component.

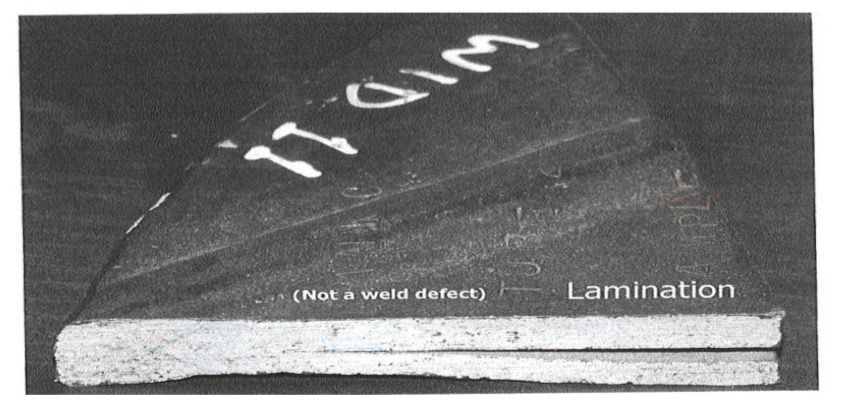

Laminations (in flat plates)

Laminations are planar voids usually aligned parallel to the surface of the material. They may be the result of any original casting defect enlarged and flattened.

The most common original casting defect 10 likely to form a lamination is secondary piping.

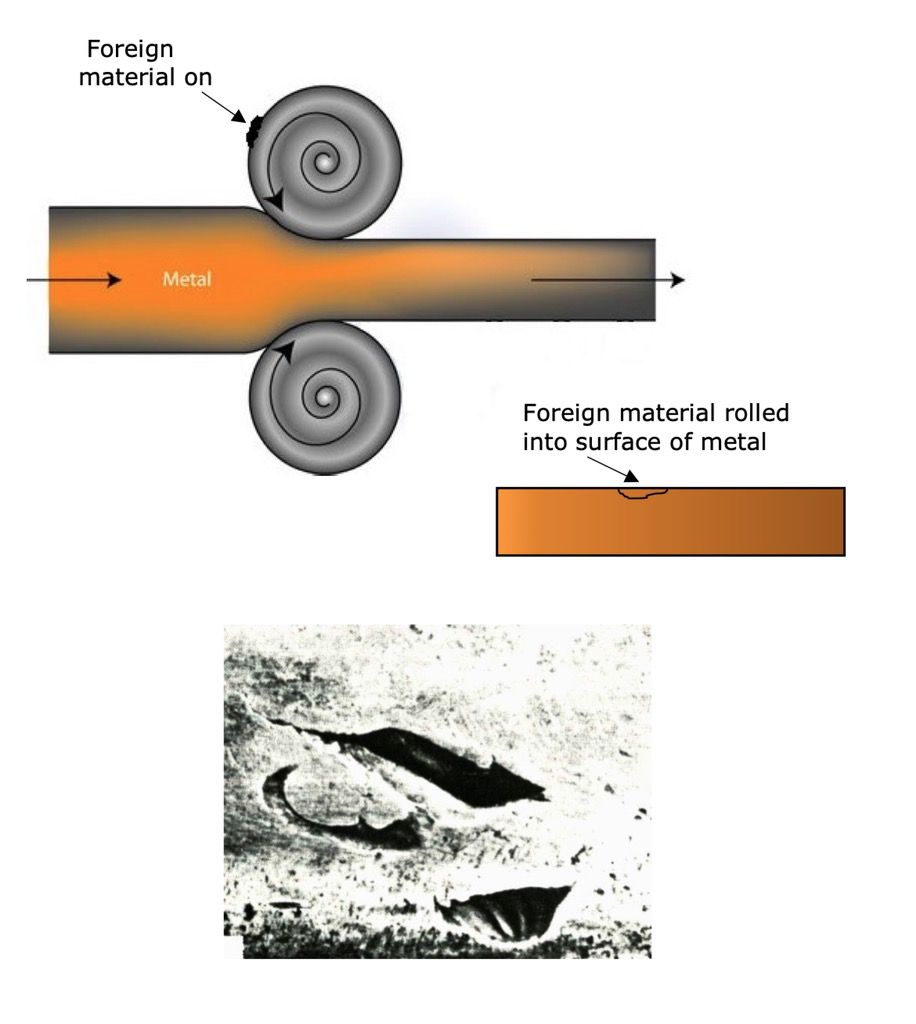

Slugs

A slug is a piece of foreign material which has been processed or rolled into the surface of a wrought material.

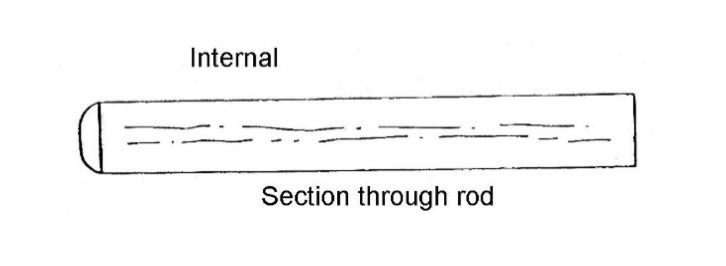

Stringers (in bar stock)

As a billet is rolled into a bar section, any non-metallic inclusions are squeezed out into longer and thinner defects. These are called stringers and often appear as intermittent linear indications.

Seams and laps (in bar stock)

During the rolling operation, faulty, oversized dies, surface cracks or any surface irregularities may cause laps or seams.

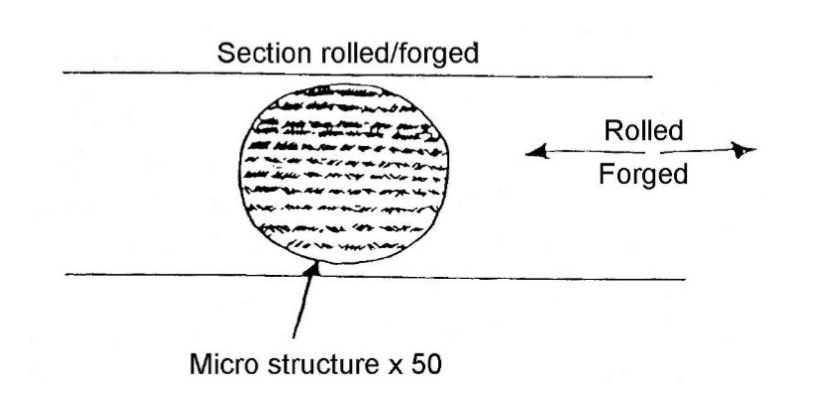

Banding

As the ingot is forged and rolled, the segregations are elongated and reduced in cross-section. If further processing is carried out, they may appear as very thin parallel lines or bands and is generally known as banding. Banding is not usually considered significant.

Note: Banding can be made visible to the naked eye by acid etching or often by magnetic particle inspection (since a change in magnetic permeability occurs between the base material and the segregates) the edge of wrought plate.

Flakes

Internal ruptures usually associated with hydrogen and nitrogen and often found in heavy alloy steel forgings. Flakes are caused during cooling and, being internal, are seldom found by magnetic or penetrant testing.

Clinks

A form of cracking occurring due to a rapid thermal gradient, so called due to the sound created as the material spontaneously cracks, usually associated with large forgings or high strength materials when rapidly cooled for high (working) temperatures.

Slivers

Where the metal has been scarfed, usually to remove visible surface defects and burning torches have not evenly melted/ removed the surface it can leave ridges on the surface and when the material is re rolled the ridges are pushed into the material surface being fused at one end only to the base material, this is also sometimes referred to as fash.

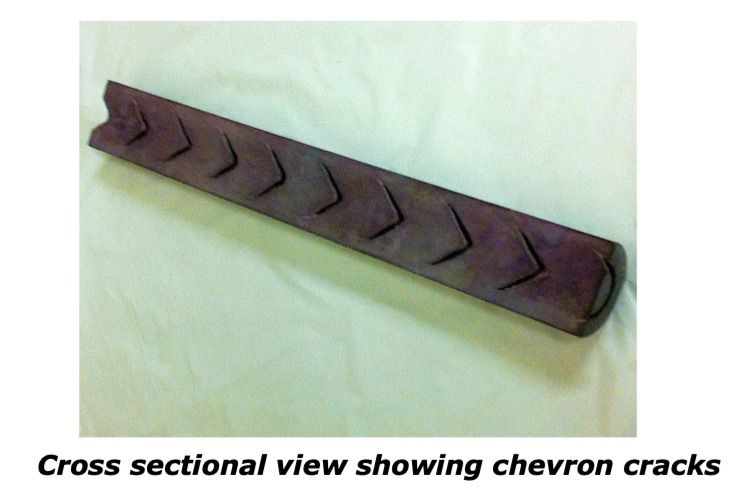

Chevron Cracks (Cone Cracking)

A subsurface defect associated with the extrusion process when the material deformation rate at the contact of the dies is excessively different to that of the central area of the product resulting in stresses beyond the plastic flow capability of the material and a rupture occurs, often at regular intervals along the length of the product.